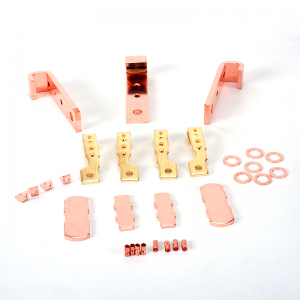

Non-Standard Stamping Parts Los ntawm Tuam Tshoj Manufacturers

Hluav taws xob stamping qhov chaw xa mus rau cov khoom siv kho vajtse siv rau cov khoom siv hluav taws xob.Muaj ntau ntau yam khoom siv rau cov khoom siv hluav taws xob.Cov khoom siv hluav taws xob feem ntau pom cov kws tshaj lij stamping qhov chaw tsim khoom sab nraud los tsim cov khoom siv rau cov khoom siv hluav taws xob.

Qhov zoo ntawm hluav taws xob stamping qhov chaw

(1) Kev ua haujlwm ntawm hluav taws xob stamping yog siab, thiab kev ua haujlwm yooj yim, thiab nws yooj yim rau kev paub txog tshuab thiab automation.Qhov no yog vim tias stamping nyob ntawm qhov tuag thiab cov khoom siv stamping kom tiav cov txheej txheem.Tus naj npawb ntawm strokes ntawm cov xovxwm zoo tib yam tuaj yeem ncav cuag kaum ob ib feeb, thiab lub siab ceev tuaj yeem ncav cuag ntau pua lossis ntau txhiab tus hauv ib feeb, thiab txhua qhov kev tawm dag zog tuaj yeem tau txais punch.

(2) Thaum stamping cov khoom siv hluav taws xob, vim tias qhov tuag ua kom qhov loj thiab cov duab raug ntawm cov khoom stamping, thiab feem ntau tsis ua rau qhov zoo ntawm qhov chaw stamping, thiab lub neej ntawm cov tuag feem ntau yog ntev, lub stamping zoo yog ruaj khov. , interchangeability yog zoo, thiab nws muaj cov yam ntxwv ntawm "zoo tib yam".

(3) Cov khoom siv hluav taws xob tuaj yeem ua cov khoom siv nrog ntau qhov loj thiab cov duab zoo, xws li cov khoom siv me me ntawm cov moos thiab cov watches, lub tsheb loj stringers thiab npog, thiab lwm yam. Ntxiv rau qhov txias deformation hardening nyhuv ntawm cov ntaub ntawv thaum lub sij hawm stamping, lub zog thiab rigidity. ntawm stamping yog siab.

(4) Hluav taws xob stamping feem ntau tsis tsim cov chips thiab chips, thiab siv cov khoom siv tsawg dua, thiab tsis xav tau lwm yam khoom siv cua sov.Yog li ntawd, nws yog ib qho khoom txuag thiab txuag hluav taws xob ua, thiab tus nqi ntawm cov khoom stamping yog tsawg.

Cov khoom nyoos

Peb txhawb nqa txhua yam khoom siv hlau.Liab tooj liab, tooj dag, tooj liab hmoov, tooj liab clad steel, 45 # steel phaj, 304, tshiab dawb tooj liab, txhuas, castings, thiab lwm yam.

Khoom nta:

High dimensional precision, kaw blanking

Tsawg kev tshem tawm, tus nqi qis thiab kev ua haujlwm siab;

Txheej txheem kev kho mob:

Txiav, xuas nrig ntaus, nplua txiav, sib tsoo, polishing, sib tsoo, sib sau, luam ntawv, drilling, chamfering, reaming, tu, shaping, roj immersion, degreasing, thiab lwm yam

Kev ua kom muaj nuj nqis: tsis muaj kev txwv rau qhov ntau, thiab qhov loj dua qhov ntau, qhov zoo dua.

Txoj kev hais lus: kev sib tham hauv hluav taws xob, email, hais lus.

1. Raws li kev ua haujlwm nyuaj ntawm hardware stamping qauv lossis kos duab;?

2. Cov sijhawm ua haujlwm ntawm cov khoom, cov khoom siv thiab cov pwm yuav tsum tau ua;

3. Kev kam rau ua kom raug ntawm qhov chaw;

4. Lwm yam kev kho deg thiab cov kev cai tshwj xeeb.